Why Ralson

We are trailblazers of futuristic technology who design their tires to suit customer needs.

Innovation

Honing performance of our products (tires/tubes) through technologically backed innovation has kept us internationally competitive. Innovation within the category to offer superior value to the consumers remain a top priority for our R&D and Product Development Teams.

RESEARCH & DEVELOPMENT

Ralson’s R&D centre undertakes intense research right from the materials entry & compound design stage to the stage of product development. It is equipped with world-class instruments to do global benchmarking and gap analysis. It is recognized by DSIR, Govt. of India. It adheres to REACH regulations.

The key pillars that drive

our company's endeavours on research and development

Performance

- 30 TPI / 60 TPI / 100 TPI / 120 TPI

- Light Weight

- Strong Casing

- High density nylon fabric 60 tpi/100 tpi/120 tpi, skin wall

- EPDM and Silica reinforced material for better weather resistance

- Low rolling resistance

- Hi-Resilience compound

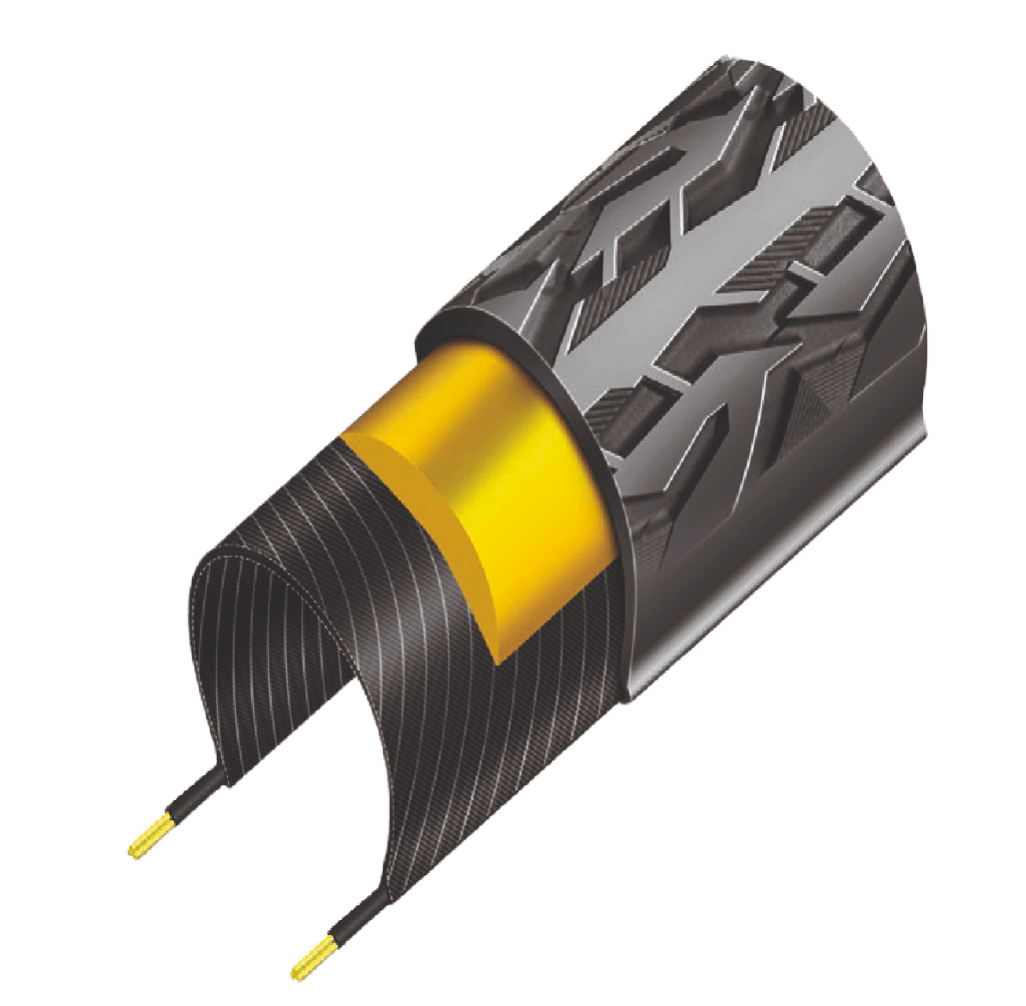

- 1mm/2mm/3mm delta guard protection layer in between the tread & casing

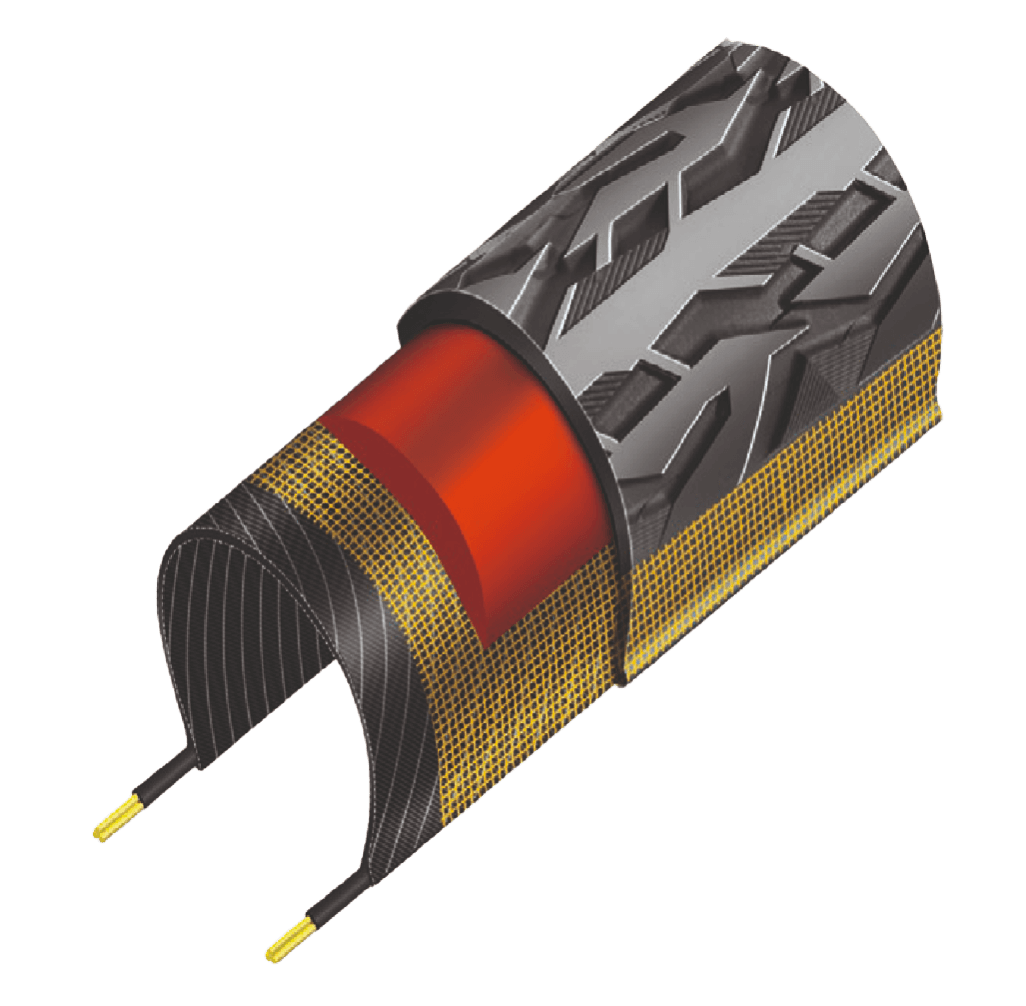

- Bead to bead viper skin fabric protection

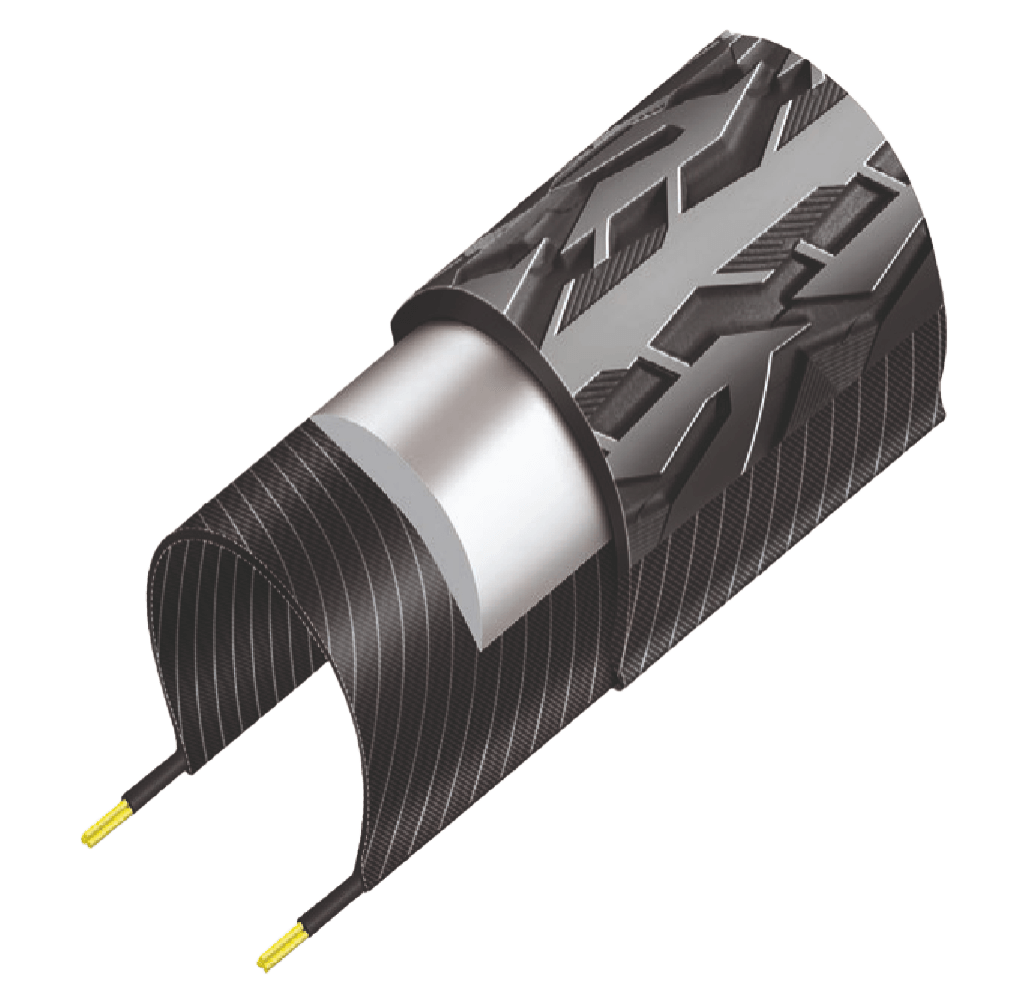

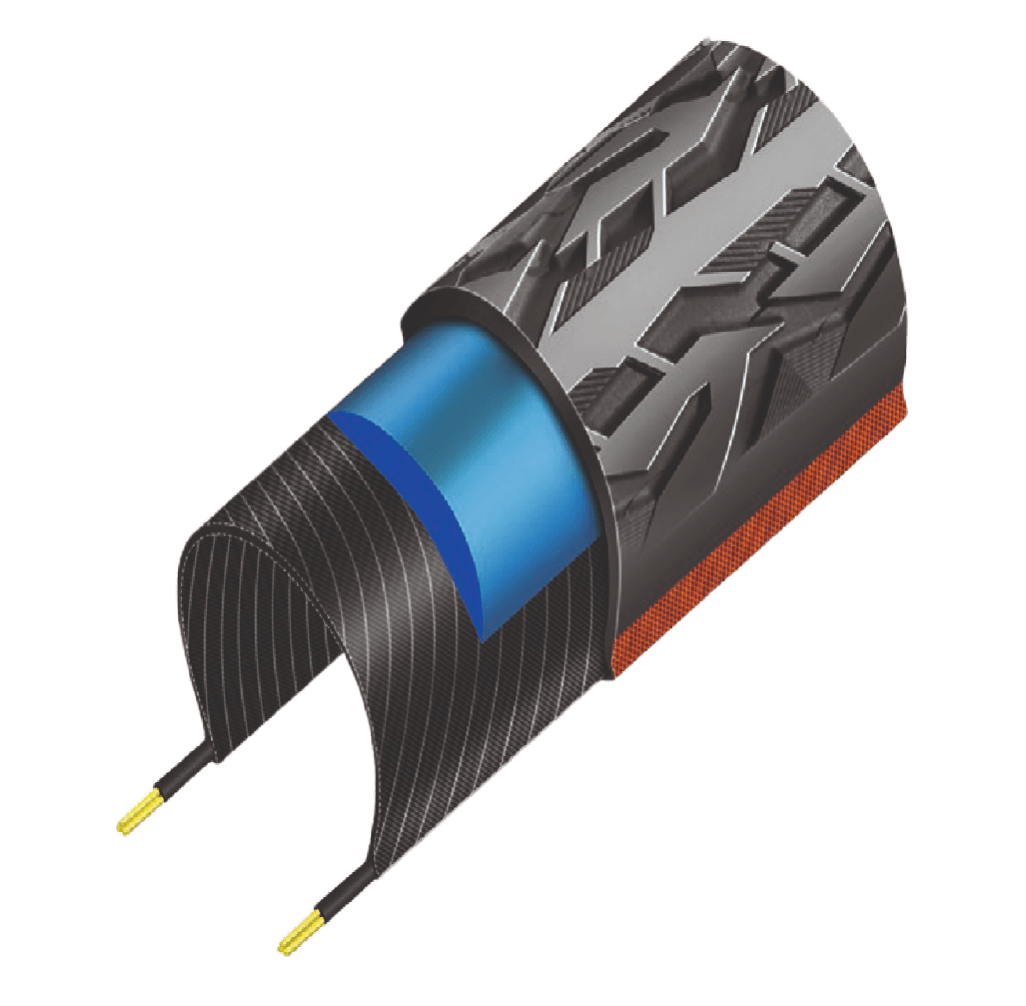

- N-6 breaker with 1.2 mm layer between the tread and casing

- 5.1

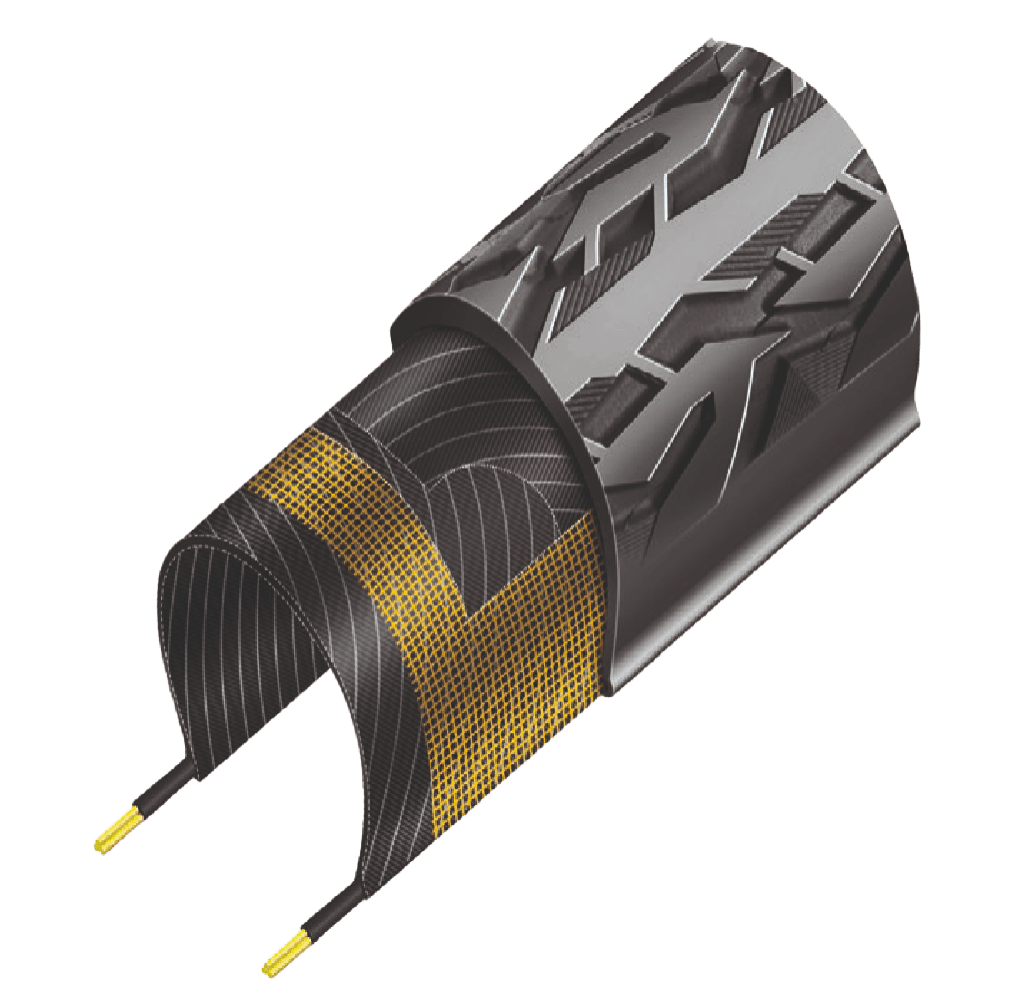

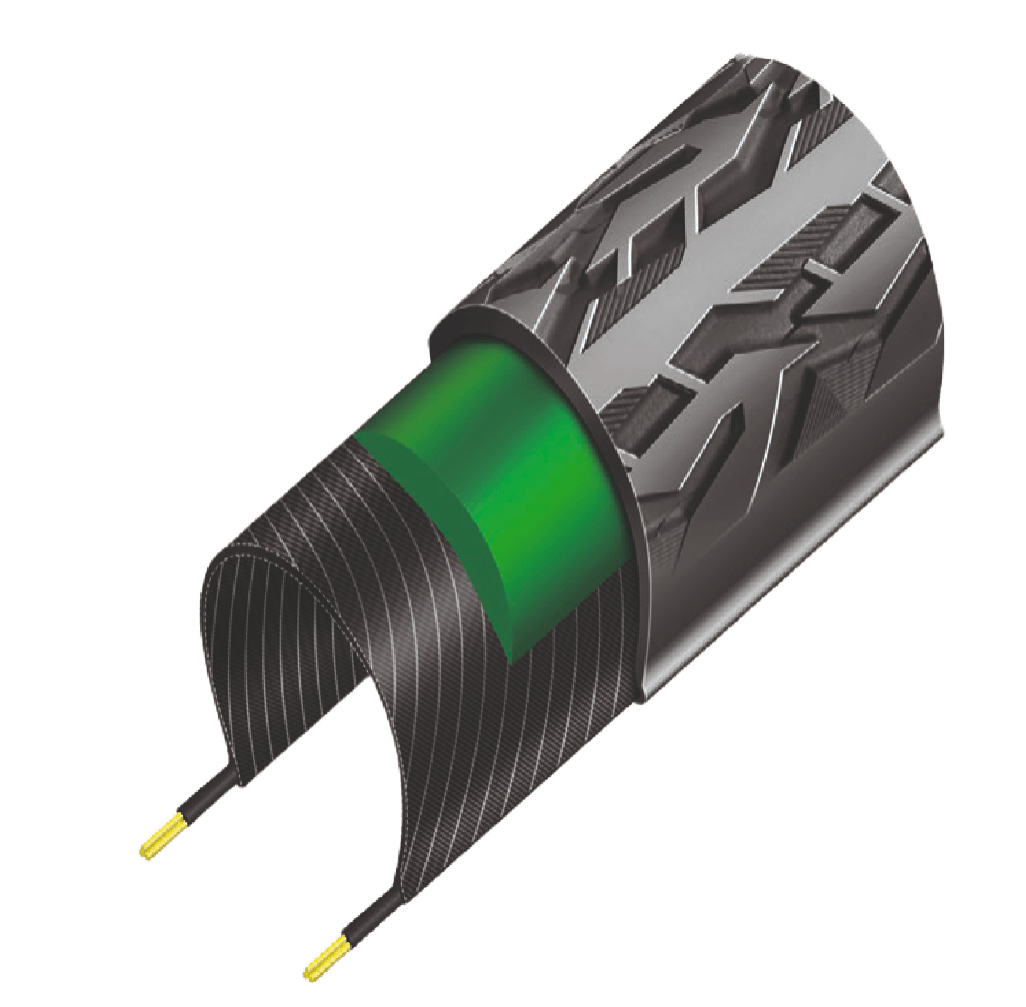

3mm green compound delta guard protection (100% Recyclable Material) - 5.2

3mm delta guard protection with high elastic compound

- Bead to Bead viper skin fabric protection

- 3mm delta guard protection layer made with hi-resilience compound between the tread and casing

- 5mm delta guard protection belt with hi-resilience compound along with chaffer on bead

- Ultra-high performance compound to provide low rolling resistance and high mileage per charge

Quality Assurance

Our labs are equipped with sophisticated testing equipment to evaluate raw materials before utilizing them. The latest machinery is used to test every aspect of the manufacturing of Ralson Tires. This ensures the finest quality of our final product.

Endurance Test

Endurance test is carried out by freely rotating the tyre on a smooth surface metal wheel or drum at a fixed speed, increasing load step-wise to certain kilometre limit or till failure.

Plunger Test

A steel needle is thrust perpendicular to the tread of a mounted and inflated tire until the tire ruptures. This test helps in assessing the structural strength of the tire.

High Speed Test

In high-speed test, tyre is rotated on drum or wheel at a step wise increasing speed at constant load, holding for a fixed period at every speed step, till failure occurs or to a minimum speed limit.

Quality Certification

The following organization quality management system has been assessed and registered by intertek testing services NA, Inc, as conforming to the requirements of ISO 9001:2015

Sedex Members Ethical Trade Audit by Eurocert inspection Pvt. Ltd

Recognition

Top Exporter of the Year (Cycle Tires) Award by CAPEXIL.

National Safety Award for the best manufacturer of rubber and plastic products by NSCI.

Best Supplier and Quality Champion awards from OEM

Tire

Finder

LET'S TALK

We're here to answer your questions

1800-1800-517

© 2022 RALSON Tires All Rights Reserved.

Lets Talkwe're here to answer your questions1800-1800-517